Product Development is a process of effective and efficient idea generation, concept development, Concept Validation, Testing and Manufacturing or implementation of a product (physical object or service) and making this process more tangible through a systematic approach.

At TecSo, We believe that to understand and come up with diligent Engineering solution for our clients’ query is our Top priority . With this vision, We have imbued some of the virtues like On time delivery ,competitive budget, Best-In-Class solution, Proactive market assessment and many more in heart of our organization which proves ourselves as a global player in Product Design and Development.

Backhoe Loader

Telehandler

Tandem Roller

Excavator

Our Functional area for product development covers :

- Conceptual Iterative calculations for product design.

- Concept Design of parts, sheet-metal components and assemblies.

- Detailed Engineering Design and Manufacturing Drawings.

- Manufacturing assistance and supplier selection.

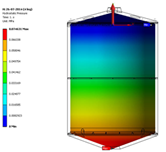

Storage Tank

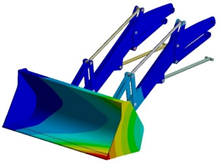

Front Loader

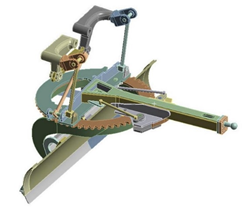

Gear Box

Motor Grader

TecSo Projects Limited provides full scale Finite Element Modeling and Analysis of product to complex vehicle engineering. We have developed our core expertise in Simulation of practical real-life situations, correlation between test and analysis data, service life prediction, design optimization, kinematic analysis and failure mode prediction. We have nurtured highly-qualified team for FEA with multi-faceted experience through a decade.

With our strong knowledge and years long experience of reverse engineering, we provide solutions to our clients as per their requirements to meet up market competitiveness.

With the years of experience on reverse engineering, Our team can understand the Engineering, fitment of its parts and functioning of large range of products and can come up with the solution as diligently as possible.Besides, we have also developed expertise to measure all kinds of profiles considering the true value of dimensions and then classify them into following measuring methods.

- Touching or Non-touching methods (include 3D Scanning Technologies and CMM)

- Deviation Analysis of physical part with CAD Model.

- Dimensional Inspection & Validation.

We follow meticulous processes that outshine customer’s expectations in terms of delivery schedules, quality and cost. Our experience on Tooling & Fixture includes design and development of welding & machining fixtures for the whole vehicle engineering of Backhoe Loader at sub assembly and final assembly levels. Such assemblies include Boom, Dipper, Links, Loader arm, Bucket, Cabin, Operator platform, Fender etc.

We provide a software related training for student as well as professonal.